Description

The JCS Combi Check is the ideal solution for the complete end-of-line inspection of your product. This metal detector and check weigher combination detects products with metal contaminations and checks the weight of each product.

Checkweigher

The JCS Checkweigher comes with an OIML R51 Type approval from the NMI. Combined with the user-friendly software, it is ideally suited to E-weighing, approved weighings and internal control weighings.

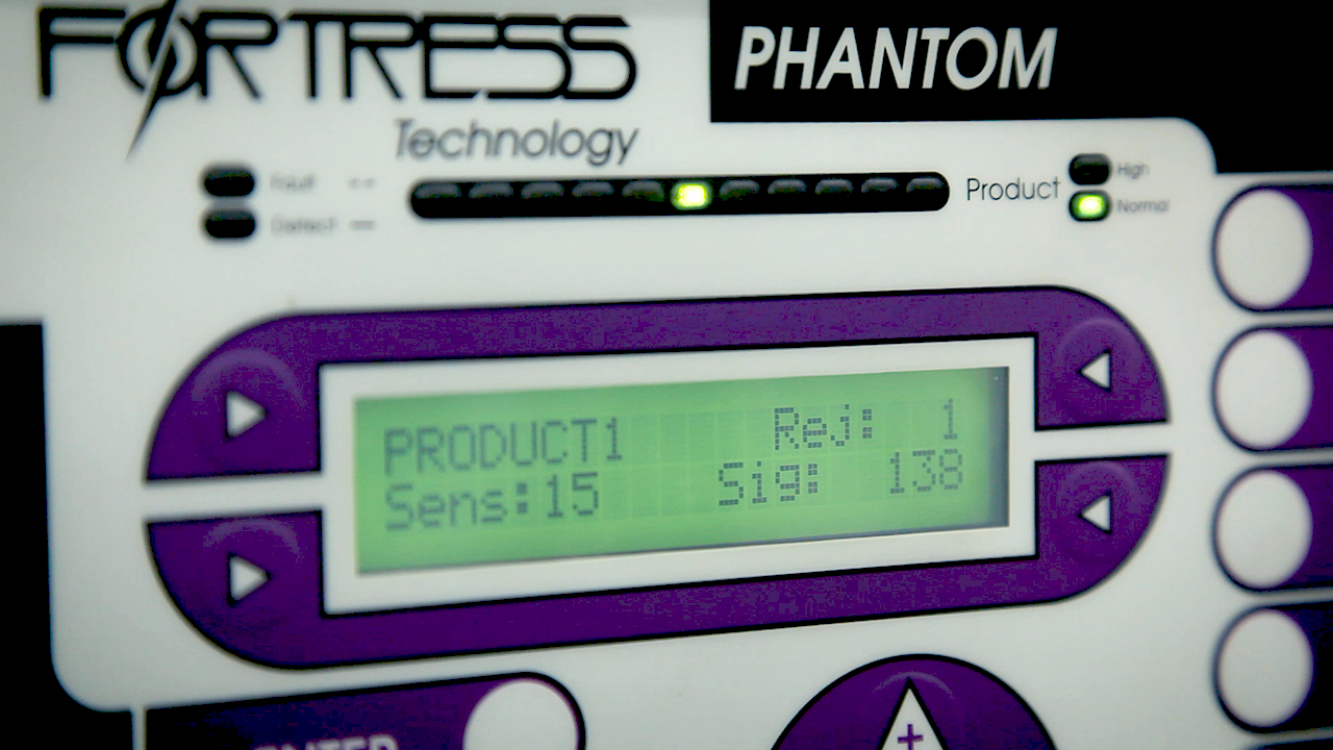

Metal Detector

For the detecting of metal contaminations we make use of a Fortress metal detector. FORTRESS metal detectors use the very latest digital technology to detect and remove ferrous and non-ferrous metals, including stainless steel (316). The standard metal detector has a stainless steel body and can be delivered with any desired opening size. The extra robust housing, certified according to IP69K, is used for extra stability and improved performance in wet conditions.

Robust Check Point

The JCS Combi Check combines the best of both worlds in an open hygienic construction. This robust machine is resistant to the most extreme production conditions and can be cleaned under high pressure.

Important features

- OIML R51 Type approval from the NMI

- Approved software

- A spacious memory menu for saving product specifications.

- Automatic reset

- Automatic calibration

- Automatic test procedure

- User-friendly touchscreen

- Anti Floor Vibration loadcell

- Robust frame with collision protection

- Can be simply repositioned with a pump truck (hand pallet truck)

- Range of ejection principles available

- Range of readout options

Specifications

| Measuring range | 50 – 4.000 g / 150 – 20.000 g |

| Weighing precision | 2 gram (in accordance with the Metrology Act) |

| Max. no. checks | 135 wpm (weighings per minute) |

| Max. speed | 84 m/min (depending on product, product length and product supply) |

| Metal Detector | Metal Detector Fortress |

| Dimensions Opening (W X H) | Diameter width: 25 – 1525mm x diameter height: 25 - 635mm (special sizes available) |

| Belt type | Modular acetal |

| Communication | RS485 / Optional: Ethernet/wireless |

| Alarm | Sound signal / warning light |

| Options | Separate display / Portable display / Ejection system / Contact Software |

| Construction | Stainless steel 304 / plastic (FDA) |

| Protection | IP69K |

| Power | 230 V |

Downloads

The JCS Combi Check is the ideal solution for the complete end-of-line inspection of your product. This metal detector and check weigher combination detects products with metal contaminations and checks the weight of each product.

End-of-Line inspection for the food industry

Jansen Control Systems supplies and maintains a range of end-of-line inspection systems. We supply our own checkweighers, FORTRESS metal detectors, SPARC X-ray systems and SOLLAU magnetic separators. Guarantee the quality of your product with one of our inspection systems. We’d be happy to help.