Description

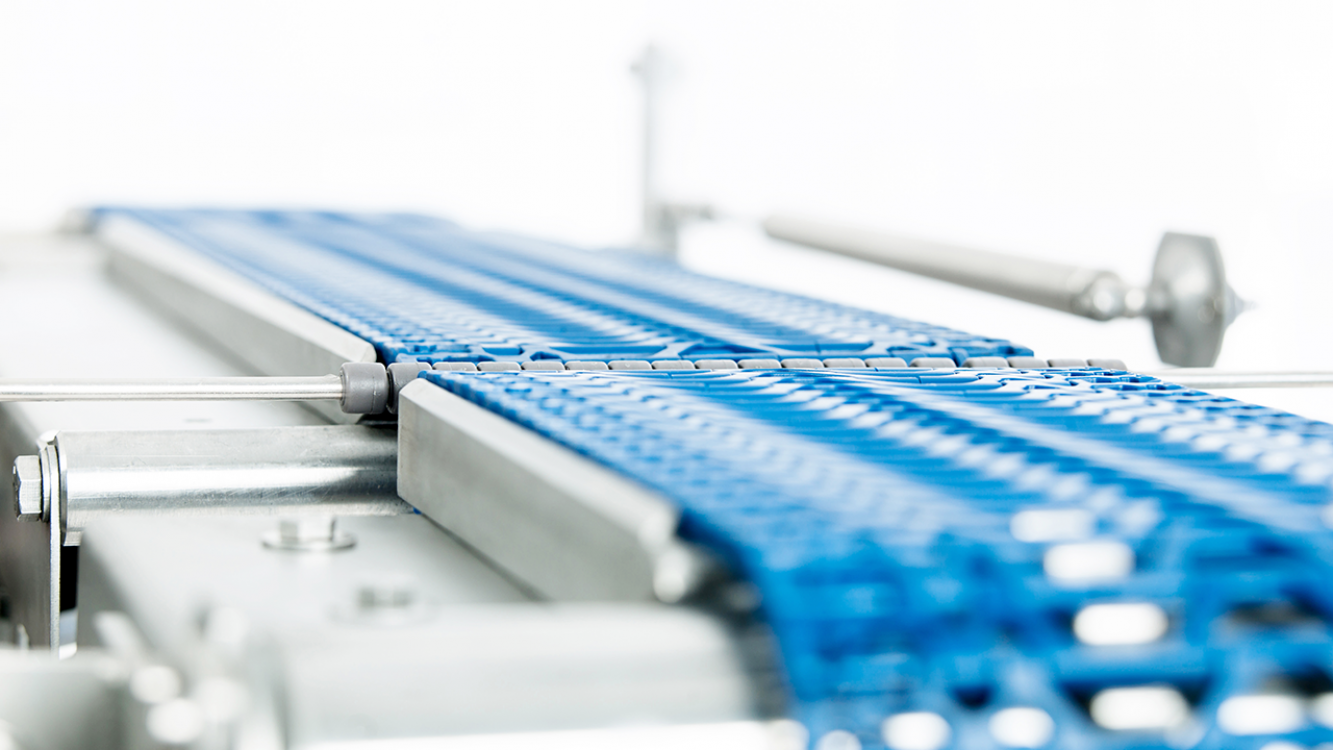

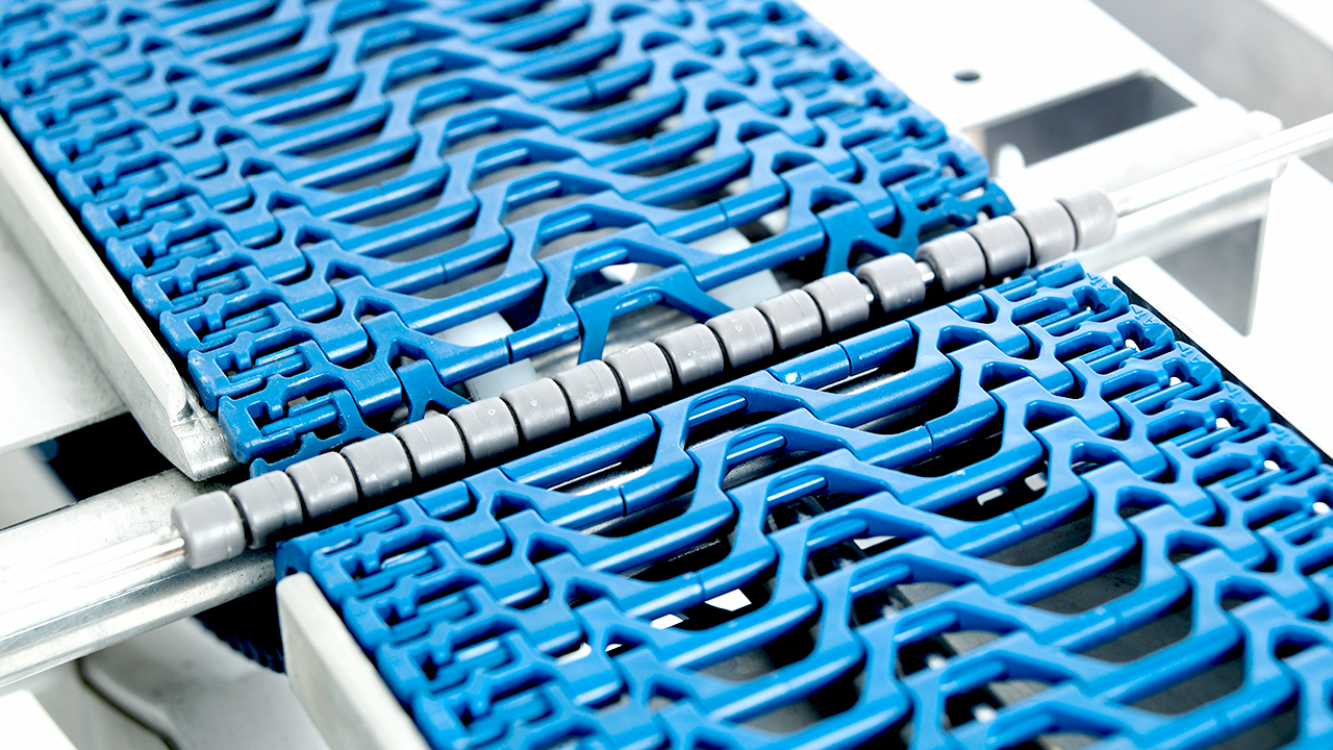

The JCS Checkweigher is the ideal solution for weighing products in the food industry. The robust, open construction and sturdy modular belts mean that the JCS Checkweigher is resistant to the most extreme production conditions and can be cleaned under high pressure.

The JCS Checkweigher is not simply robust, it is also highly precise and comes with an OIML R51 Type approval from the NMI. Combined with the user-friendly software, it is ideally suited to E-weighing, approved weighings and internal control weighings.

Software

The JCS Checkweigher is operated using a user-friendly touchscreen. Programs can be easily created or amended and the data collected can be saved via a USB or ethernet connection in Excel format.

Custom checkweigher

In addition to the standard design, custom checkweighers including a metal detector combinatoin are also available. This provides you with one machine for the complete end-of-line inspection of your product. The JCS Checkweigher can also be supplied with a range of ejection systems.

Important features

- OIML R51 Type approval from the NMI

- Approved software

- Automatic reset

- Automatic calibration

- User-friendly touchscreen

- Anti Floor Vibration loadcell

- Robust frame with collision protection

- Can be simply repositioned with a pump truck (hand pallet truck)

- Range of ejection principles available

- Range of readout options

Specifications

| Applications | E-weighing, calibrated weighing and control weighings |

| Measuring range | 50 – 4.000 g / 150 – 20.000 g |

| Weighing precision | 2 gram (in accordance with the Metrology Act) |

| Max. no. checks | 135 wpm (weighings per minute) |

| Max. no. recipes | 250 different products to be set |

| Max. speed | 84 m/min (depending on product, product length and product supply) |

| Belt type | Modular acetal |

| Belt length | 680 mm |

| Belt width | 355 mm |

| Construction | Stainless steel 304 / plastic (FDA) |

| Protection | IP67 |

| Power | 230 V |

Downloads

The JCS Checkweigher has been constructed to function in the most extreme production conditions. It is the ideal weighing solution for E-weighing, calibrated weighing and internal control weighings.

End-of-Line inspection for the food industry

Jansen Control Systems supplies and maintains a range of end-of-line inspection systems. We supply our own checkweighers, FORTRESS metal detectors, SPARC X-ray systems and SOLLAU magnetic separators. Guarantee the quality of your product with one of our inspection systems. We’d be happy to help.