Description

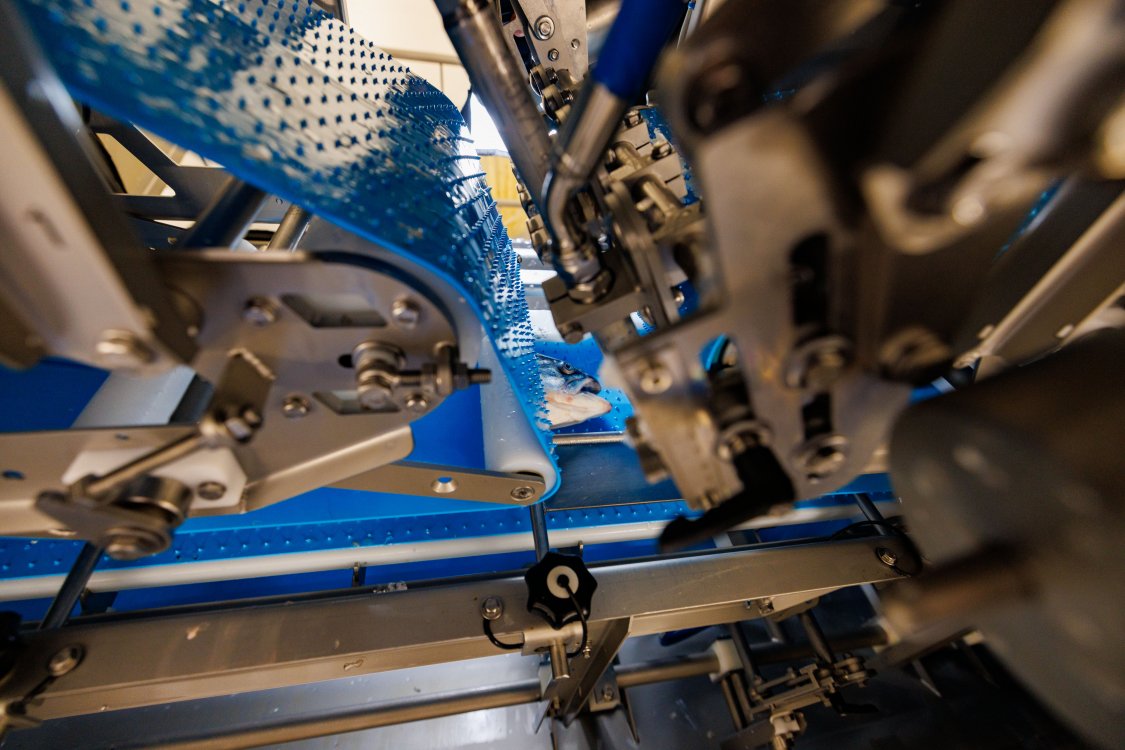

The FD15 and FD25 descalers are designed for descaling whole fish, stripped salmon and trout. The FD descaler removes the scales from fish using a high pressure water system. The use of water ensures the most efficient result, as the scales are removed without any damage to the meat. In addition to the scales, the machine also effectively removes mucus and bacteria such as salmonella listeria from the fish.

How the descaler works

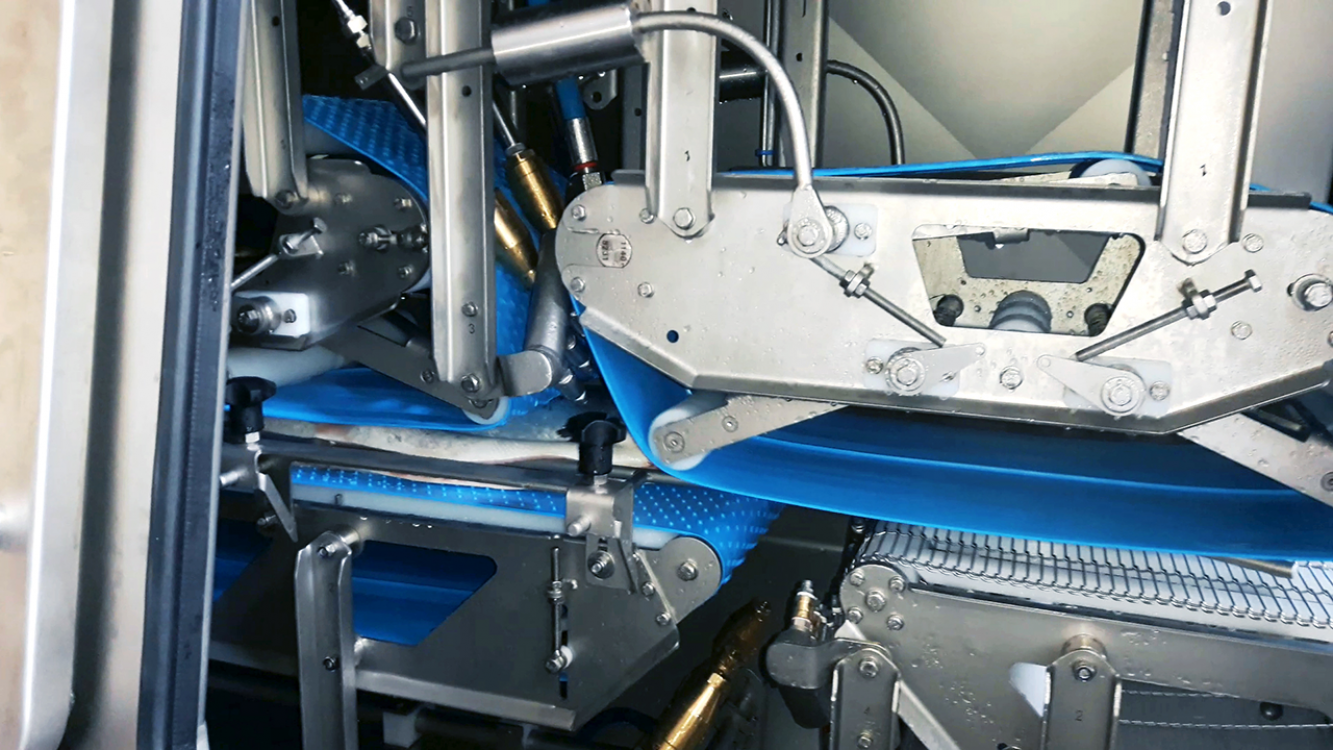

The fish is fed into the descaler and kept in place by side guides and upper and lower belts. Flat air nozzles remove the scales and mucus from the fish. No water is circulated during the process, resulting in a low bacterial cleaning process.

Robust design

The FD descaler has a hygienic design. It features an open construction with doors that can be opened to clean the machine effectively under high pressure. This prevents bacteria from building up on the surface of the machine. A further advantage offered by the doors is that plenty of light reaches the machine during cleaning. The machine features a control cabinet, and the height of the machine can be adjusted as the customer wishes.

The FD descaler is available in a single (FD15) or double (FD25) version

Specifications

| Number of operators | 1 |

| Capacity | FD15: 14-16 fish/min FD25:up to 25 fish/min |

| Dimensions (LxWxH) | ± 2.980/3.800 x 1.100 x 1.700mm |

| Fish sizes | To be agreed upon |

| Construction | SS 316 / HMPE |

| IP Rating | IP67K |

| Power Supply | 3 x 400/230 V + PE, FD15: IB = 42 A / 62A |

| Water consumption | ± 50/100 l / min, ± 80/120 bar / |

| Water connection | 3/4” / 3 bar |

Downloads

The FD15 and FD25 descalers effectively remove scales, mucus and bacteria from fish without damaging the meat. It uses a high pressure water system and is suitable for whole fish, stripped salmon and trout.

Mechanical engineering in the food industry

Jansen Techniek specialises in custom mechanical engineering for the food industry. We’re always on the move, and develop solutions aimed at optimising the production processes for our customers every day. In addition to descalers, we supply many other systems including conveyor belts, box tippers, flow weighers, denesters and Flat Fish Gutting machines.

Almost every system we construct is unique. Tailored entirely to your situation.