Description

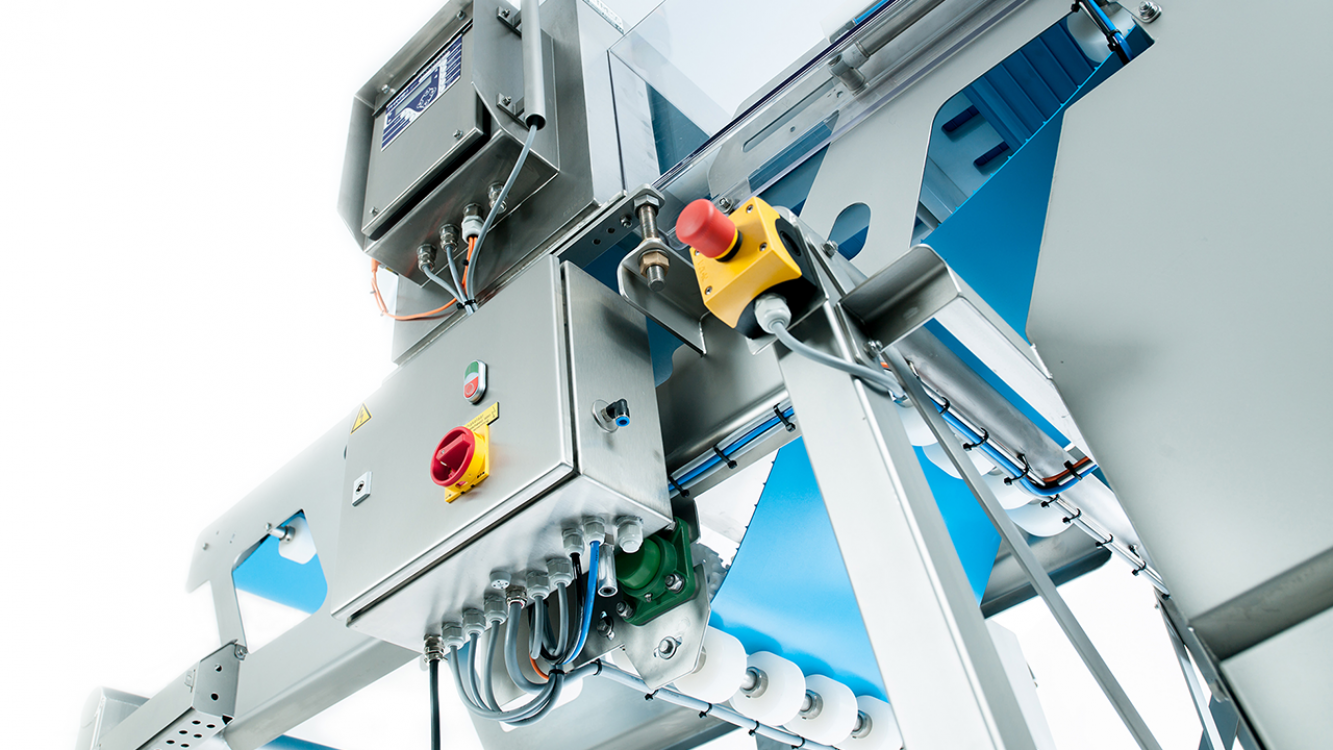

FORTRESS belt metal detectors use the very latest digital technology to detect and remove ferrous and non-ferrous metals, including stainless steel. FORTRESS belt metal detectors are available in aluminium or stainless steel with a wide selection of opening sizes and have a robust construction to cope with even the heaviest applications. The BSH extra robust housing, certified according to IP69K is used for extra stability and improved performance in wet conditions.

Stealth and Interceptor models

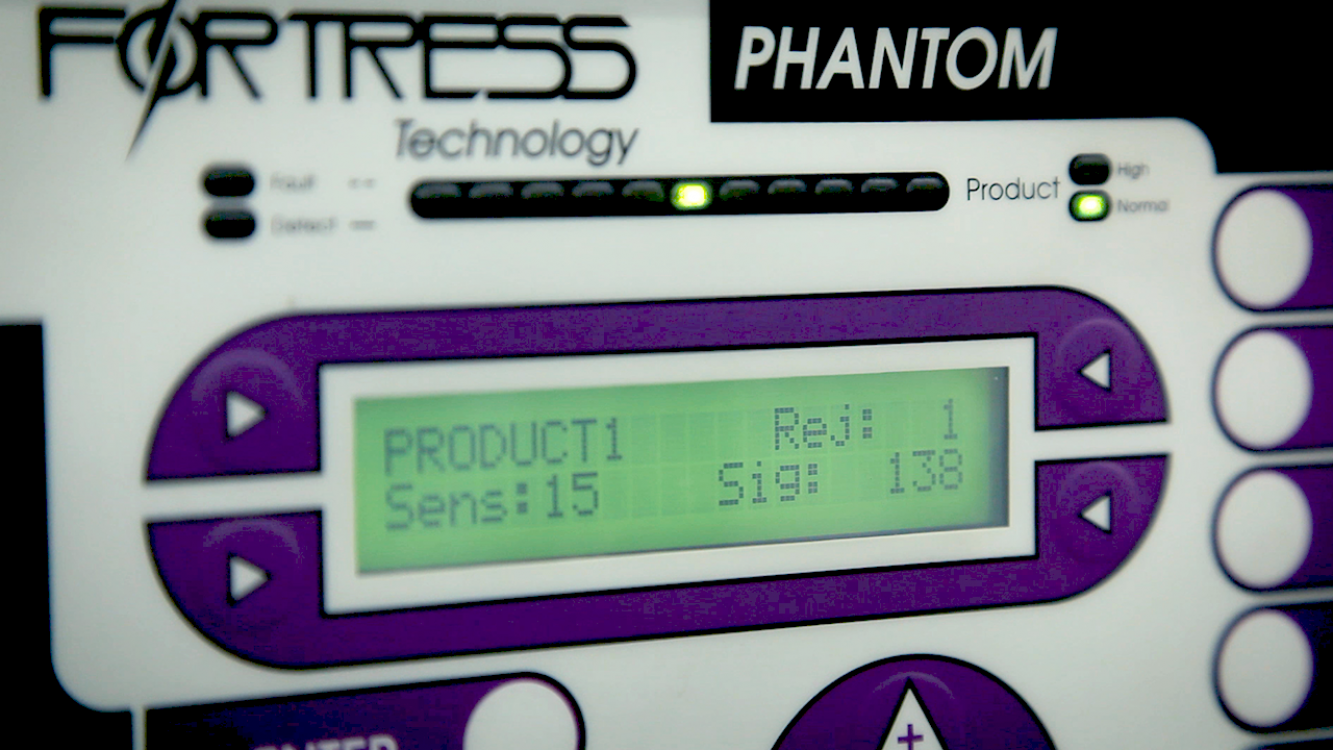

The Fortress Stealth metal detector is the standard model suitable for most standard situations. For more detection strength Fortress supplies the Interceptor models, with the Interceptor DF for the detection of ultra-thin contaminants that are often encountered in processing lines. This model was developed with a divergent field technology, which is the world’s first metal detector to use multiple field directions. This greatly improves the detection of ultra-thin contaminants with detection levels on par with the latest X-Ray systems in some applications.

Jansen combination

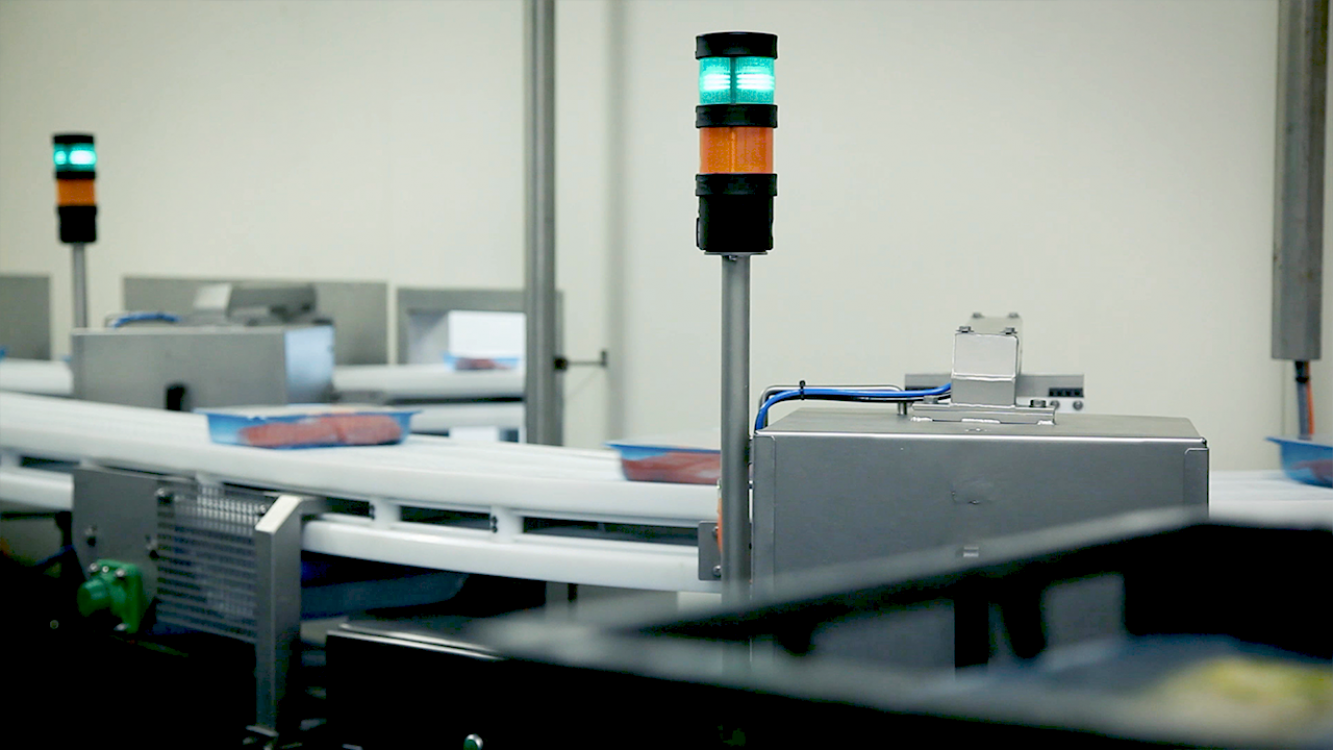

FORTRESS belt metal detectors can be supplied including the Jansen Techniek transport system (with or without reject system), but can also be integrated into existing conveyor belts or supplied as loose detector head.

Belt metal detector applications

Bakeries, Meat, Chicken, Fish, AGF, Dairy, Packaged products, Ready meals, Healthcare, Sweets, Fresh/chilled/frozen foods and many other products and sectors.

Important features

- Automatic balancing

- Automatic calibration

- A spacious memory menu for saving product specifications.

- Serial interface for saving data on the computer (excluding Contact software)

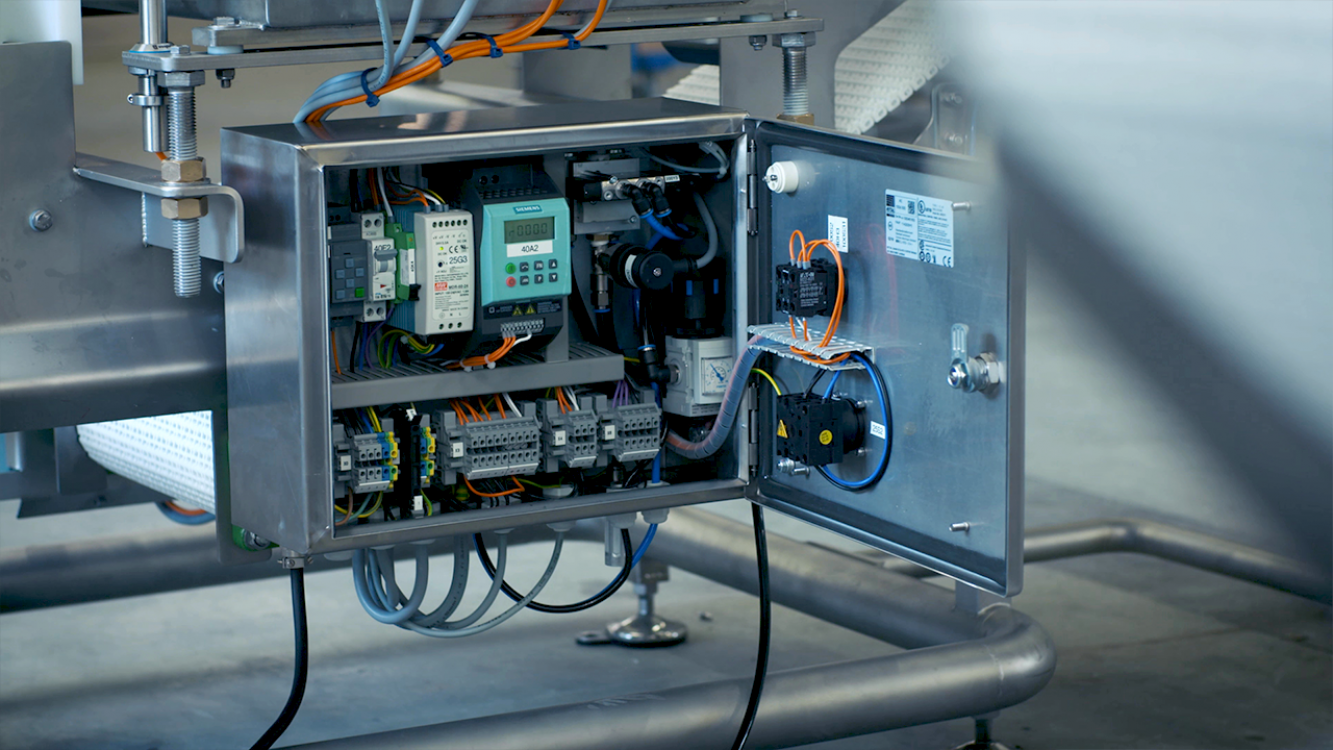

- Modular exchangeable electronics

- Automatic test procedure

- Water and dust resistant (IP69K). No sealant edges, welded all the way around.

In practice

Specifications

| Construction | Lacquered epoxy aluminium or stainless steel 304 |

| Dimensions (W X H) | Diameter width: 25 – 1525mm x diameter height: 25 - 635mm (special sizes available) |

| Detector state | Horizontal or vertical |

| Protection | IP 65 aluminium / IP69K / Nema 4X (stainless steel with BSH) |

| Power | 230V |

| Communication | RS485 / Optional: Ethernet/wireless |

| Alarm | Sound signal / warning light |

| Options | Separate display / Portable display / Ejection system / Contact Software |

| Display type | Standard Stealth / Optional Interceptor |

Downloads

FORTRESS belt metal detectors use the very latest digital technology to detect and remove ferrous and non-ferrous metals, including stainless steel. FORTRESS belt metal detectors are available in aluminium or stainless steel with a wide selection of opening sizes. As a representative of FORTRESS, we supply a range of other metal detector types in addition to belt metal detectors.

End-of-Line inspection for the food industry

Jansen Control Systems supplies and maintains a range of end-of-line inspection systems. We supply our own checkweighers, FORTRESS metal detectors, SPARC X-ray systems and SOLLAU magnetic separators. Guarantee the quality of your product with one of our inspection systems. We’d be happy to help.