Description

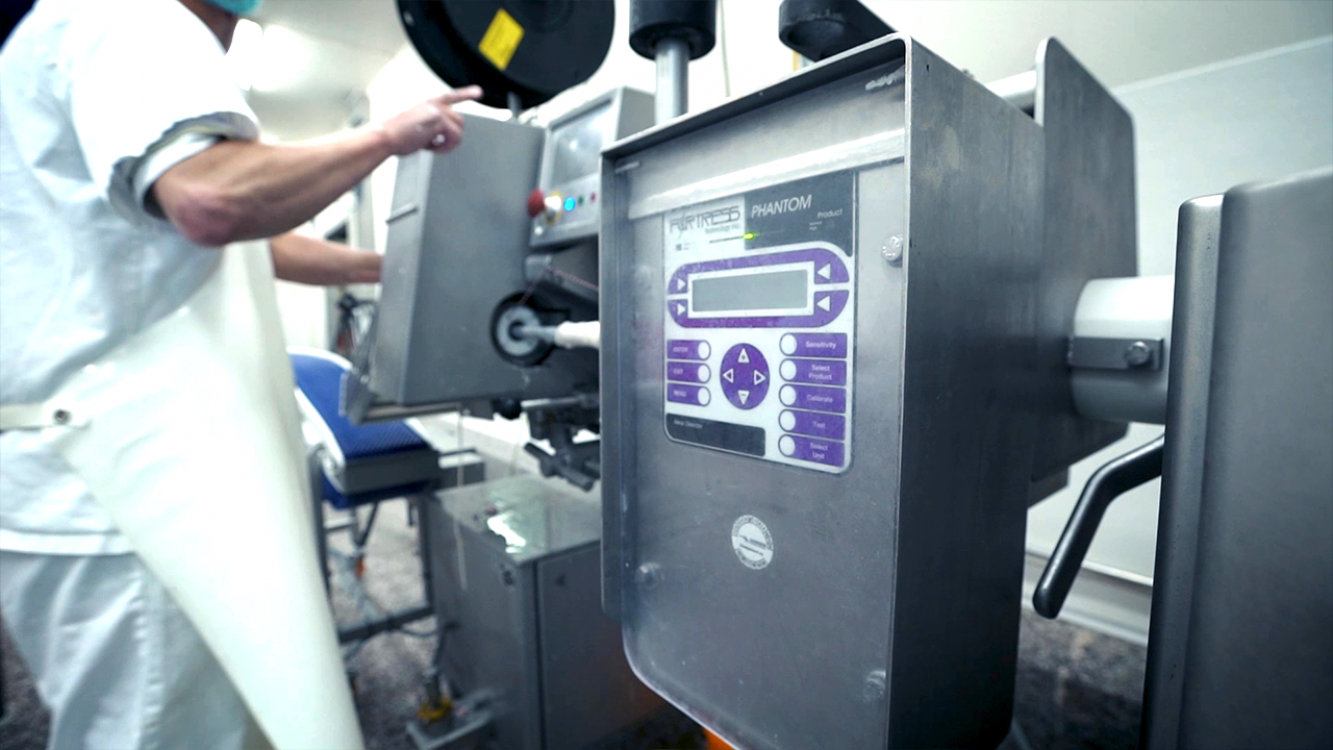

The FORTRESS metal detector for pipelines is ideally suited to inspection of pumped liquids and pastas transported via a pipe system. The system is also highly suited to inspection of meat products at the output of a vacuum/sausage machine.

FORTRESS pipeline metal detectors have a robust, stainless steel construction to be able to resist challenging production conditions. The operating display is integrated into the detector, creating a compact unit. This means that no loose cables are required to connect a separate operating panel.

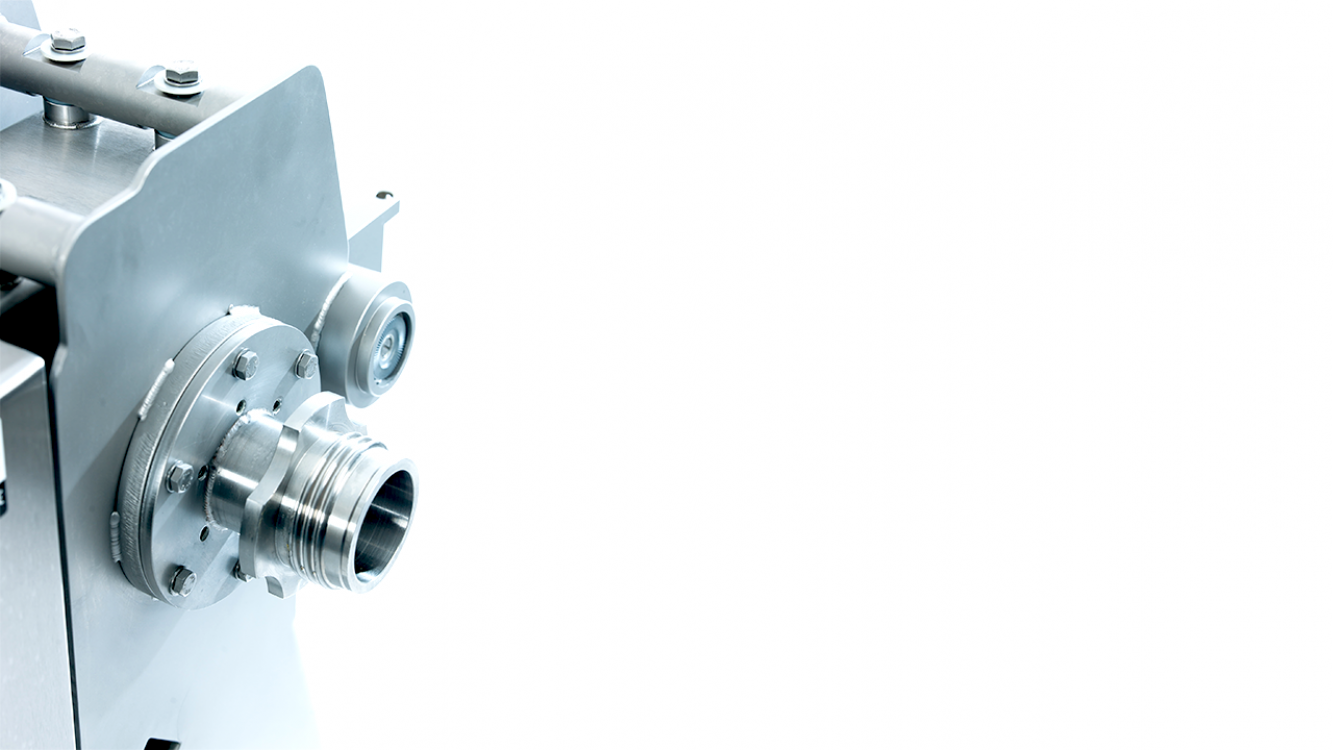

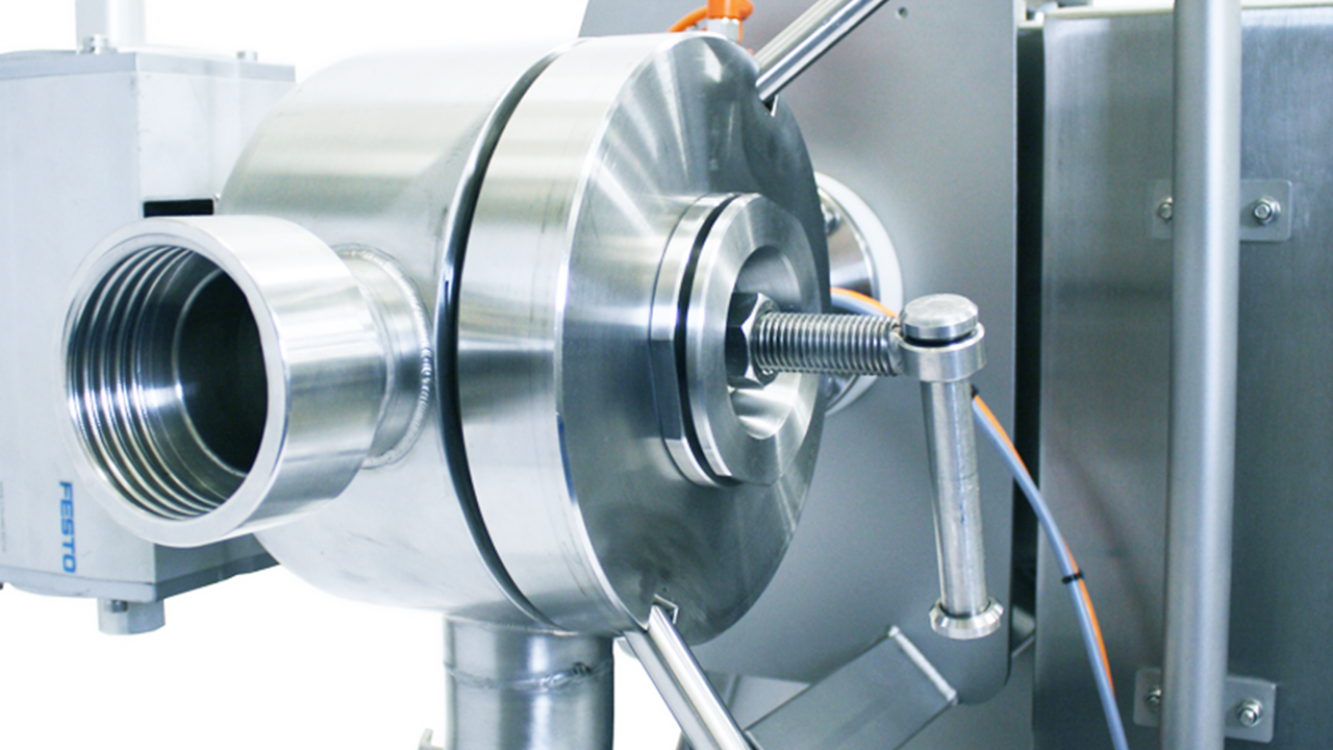

The pipeline metal detector has a very hygienic design and is nice and easy to clean. In addition, various material options are available for non-metal pipelines such as nylon, rubber and Teflon for highly demanding applications with high temperatures and/or pressure.

The pipeline detector can be extended with a Jansen Techniek 3-way valve to remove contaminated product from the stream. This valve can be very easily disassembled by hand, allowing it to be cleaned properly.

Pipeline metal detector applications

Soup, sauces, pastas, chocolate, jam, meat paste, juice, and many more products.

Important features

- Automatic balancing

- Automatic calibration

- Integrated operating panel

- A spacious memory menu for saving product specifications.

- Serial interface for saving data on the computer (excluding Contact software)

- Modular exchangeable electronics

- Automatic test procedure

- Water and dust resistant (IP69K). No sealant edges, welded all the way around

Specifications

| Construction | Stainless steel 304 |

| Display type | Standard Stealth / Optional Interceptor |

| Pipe material | Nylon / Teflon / Other food-safe plastics |

| Pipe diameter | 60 mm / 100mm (get in touch for other diameters) |

| Pressure range | 1-7 bar (wider reach possible with optional pipe style) |

| Temperature range | 10°C - 100°C (wider reach possible with optional pipe style) |

| Protection | IP69K / Nema 4X (stainless steel design) |

| Power | 230V |

| Communication | RS485 / Optional: Ethernet/wireless |

| Alarm | Sound signal / warning light |

| Connection types | Sanitary clip / Inline / RD80 |

| Options | Separate display / Portable display / Ejection system / Catch tray test balls / Heated water casing / Contact Software |

Downloads

The FORTRESS metal detector for pipelines are ideally suited to inspection of pumped liquids and pastas transported via a pipe system. The system is also highly suited to inspection of meat products at the output of a vacuum/sausage machine. As a representative of FORTRESS, we supply a range of other metal detector types in addition to pipeline metal detectors.

End-of-Line inspection for the food industry

Jansen Control Systems supplies and maintains a range of end-of-line inspection systems. We supply our own checkweighers, FORTRESS metal detectors, SPARC X-ray systems and SOLLAU magnetic separators. Guarantee the quality of your product with one of our inspection systems. We’d be happy to help.