Description

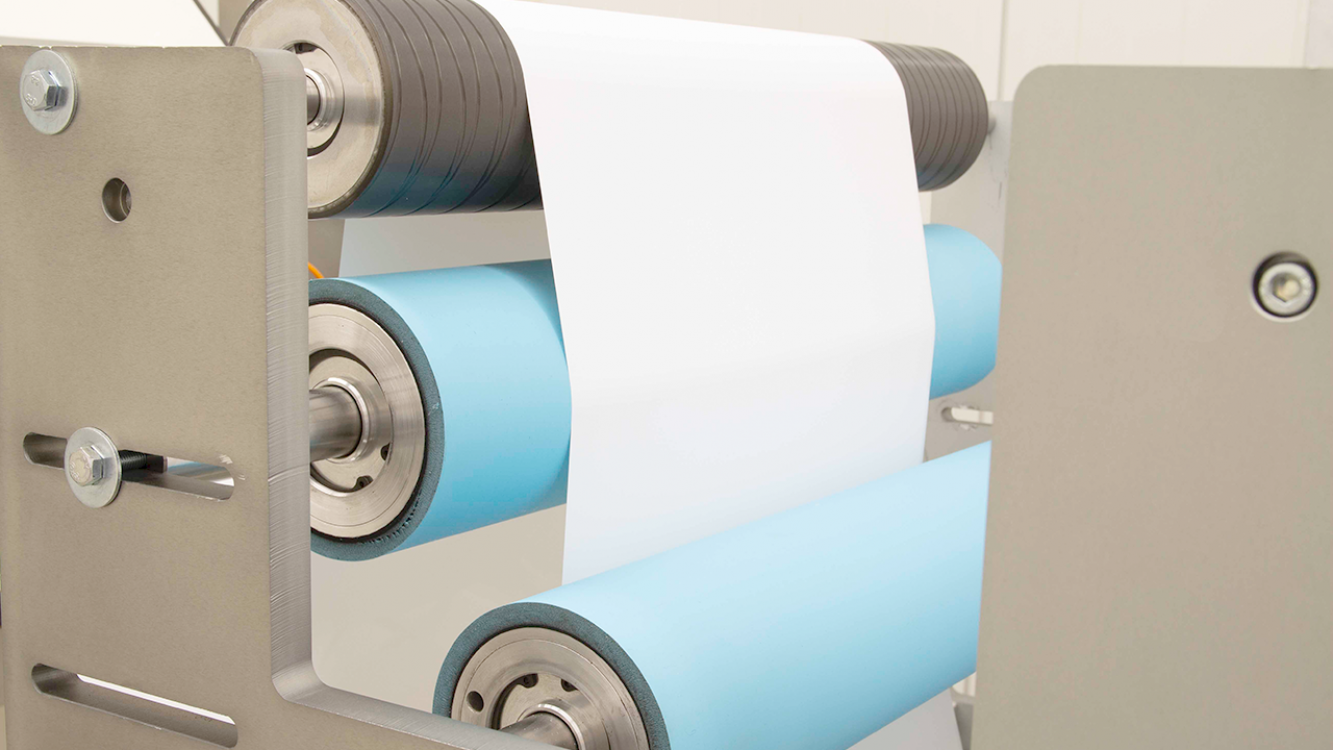

The NANOtack sticky roll cleaner is a polymer based rubber which will with its defined tackiness clean the substrate surface in direct contact down to > 0.5 µm particle size. This guarantees absolute cleanness of the surface. The installation of the roll is on the free web and as close as possible prior to the problem zone. The rubber covers come in different colour and tackiness, some antistatic, some with FDA approval for the food/pharmaceutical packaging applications.

Ionisation

In many cases electrostatic charge present on the substrate surface is a major factor in increasing contamination and makes particle removal more difficult. This is why our static control system is always installed prior to the cleaning process to guarantee a neutralised substrate surface and therefore facilitate easier removal of all particles.

Technology

The over many years special developed polymer rubber compound is brought in direct contact with the substrate. This mechanical contact and the tackiness of the roller ensure that 100% of the particles are removed from the surface. The polymer roller can be easily cleaned in regular timeframes in order to keep their tackiness over the full lifetime. The polymer has a FDA approval and can be used besides clean room applications also in the food and pharmaceutical packaging industry.

Main applications

Especially suitable for clean room applications, food- and pharmaceutical packaging, film, foil and laminate.

NANOtack System advantages

Application

- Highest possible cleaning efficiency

- 100% particle removal > 0.5 μm

- Polymer covering for all roll dimension

- Different tacks possible, anti static

- For direct or indirect cleaning

- Low investment cost

Economical

- Increased profitability

- Reduced waste and down time

Ecological

- FDA approval

- No consumables

The Hildebrand NANOtack sticky roll cleaner is a polymer based rubber which will with its defined tackiness clean the substrate surface in direct contact down to > 0.5 µm particle size. This guarantees absolute cleanness of the surface. As a representative of Hildebrand in the Netherlands we also supply other surface cleaning and electrostatic discharging systems.

End-of-Line inspection for the food industry

Jansen Control Systems supplies and maintains a range of end-of-line inspection systems. We supply our own checkweighers, FORTRESS metal detectors, SPARC X-ray systems, SOLLAU magnetic separators and HILDEBRAND electrostatic discharging and surface cleaning systems. Guarantee the quality of your product with one of our end-of-line systems. We’d be happy to help.