Description

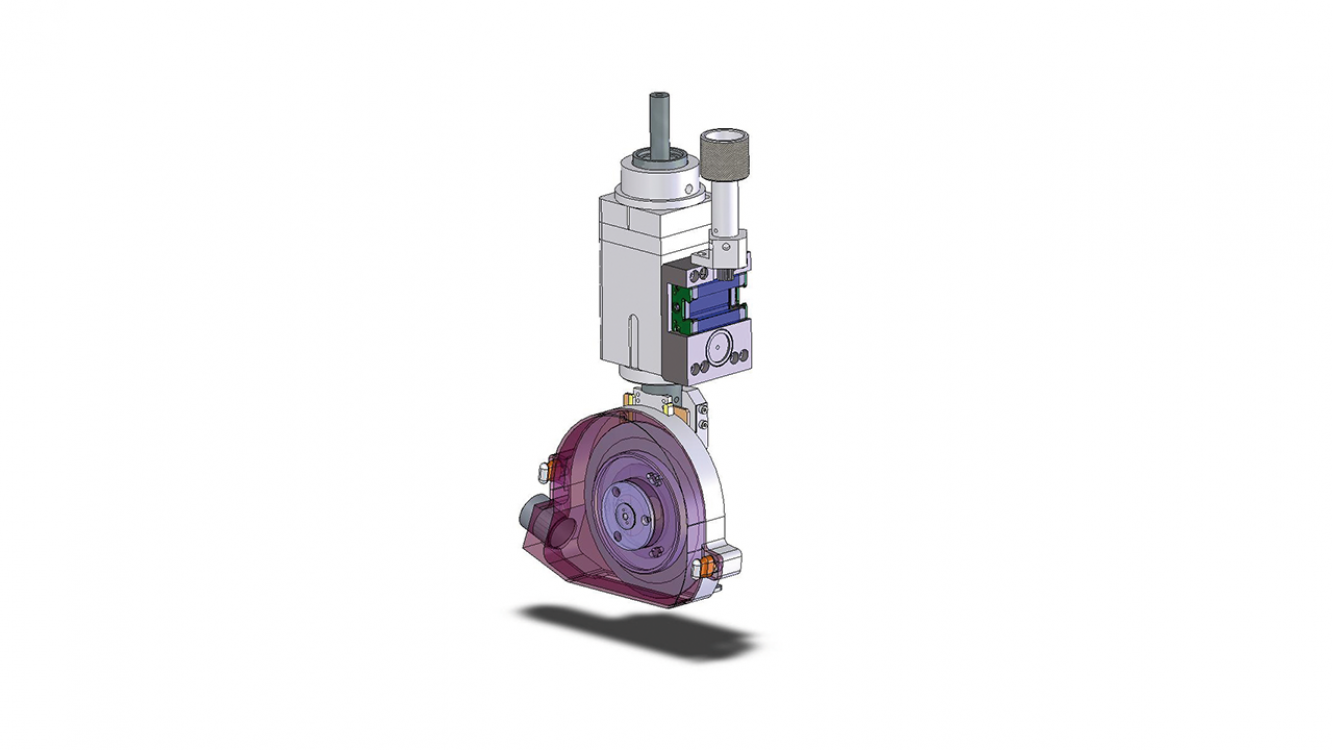

The SLITstream dust removal system for slitting units was especially developed to remove the generated dust directly at the knives. The new dust removal extraction hood generates a high air flow within the system directly at the upper knives. This extreme sharp air jet removes also the smallest particles. A blower will be mounted via a pipe system directly with the extraction hoods for each knife. A test filter can be installed to observe the efficiency of the system. After a knife change, the hood is positioned automatically. Not used knife blades are protected completely by the hood. No safety issues due to this feature during web treading.

Ionisation

In many cases electrostatic charge present on the substrate surface is a major factor in increasing contamination and makes particle removal more difficult. This is why our static control system is always installed prior to the cleaning process to guarantee a neutralised substrate surface and therefore facilitate easier removal of all particles.

Technology

The special SLITstream technology effects that a flow of >30m/sec parallel to the knife forwards the sheet run direction is generated. Especially for this we have developed an air duct in the hood along the knife. This air flow guaranties, that >95% of loose particles >30µm will be efficiently removed already during the slitting process at the knife.

Main Application

Suitable for all materials.

SLITstream System advantages

Application

- Removes > 95% of loose particles > 30μm

- Side-Flow technology for automatic self-cleaning

- Tool free opening and knife access

- Low investment cost

- Easy installation

Economical

- Increased profitability

- Reduced waste and down time

Ecological

- No consumables

- 60% lower energy consumption compared to other systems in its class

The Hildebrand SLITstream dust removal system for slitting units was especially developed to remove the generated dust directly at the knives. Thanks to an extreme sharp air jet even the smallest particles are removed. As a representative of Hildebrand in the Netherlands we also supply other surface cleaning and electrostatic discharging systems.

End-of-Line inspection for the food industry

Jansen Control Systems supplies and maintains a range of end-of-line inspection systems. We supply our own checkweighers, FORTRESS metal detectors, SPARC X-ray systems, SOLLAU magnetic separators and HILDEBRAND electrostatic discharging and surface cleaning systems. Guarantee the quality of your product with one of our end-of-line systems. We’d be happy to help.