Description

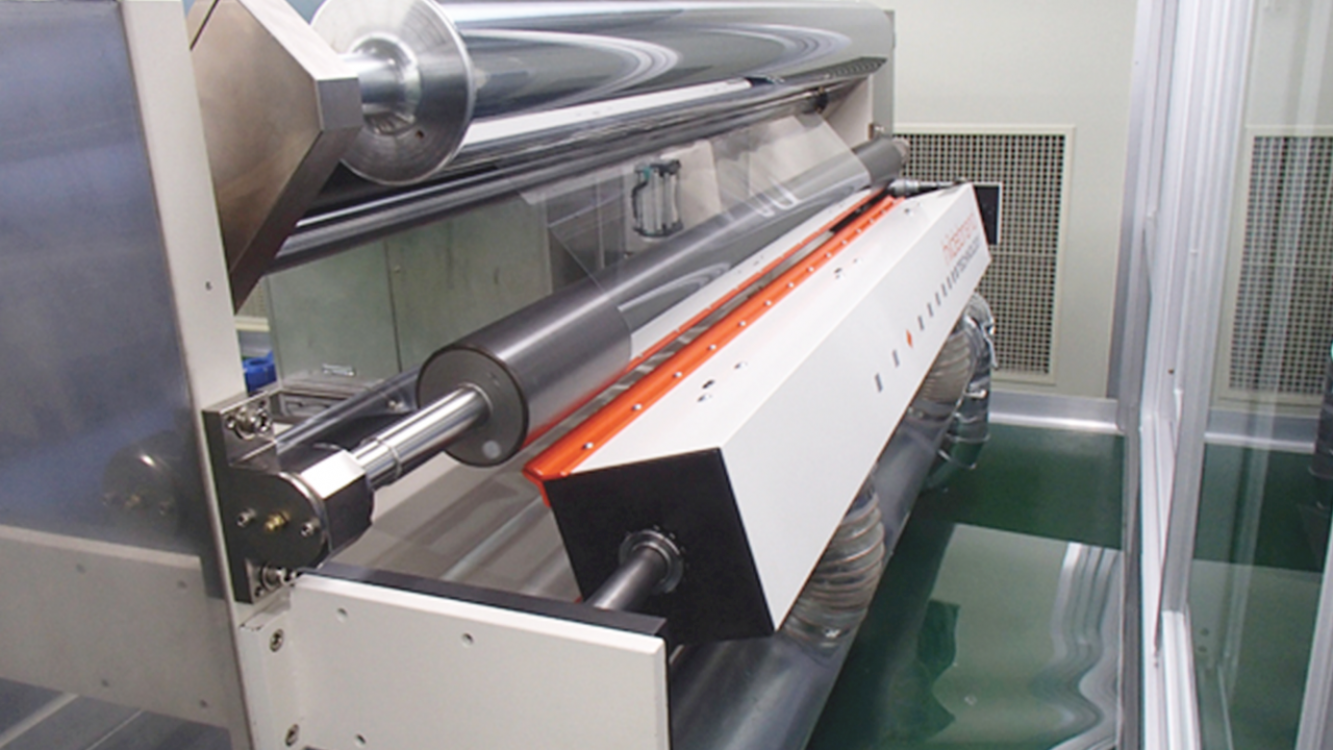

The Xstream non-contact web cleaning system adopts a revolutionary approach to improve quality, reduce down time and boost profitability. It combines the latest aerodynamic nozzle technology with a defined high speed vacuum airflow and substrate ionization prior to cleaning within one turnkey system. It is positioned above an idler roller as close as possible prior to the problem zone.

Ionisation

In many cases electrostatic charge present on the substrate surface is a major factor in increasing contamination and makes particle removal more difficult. This is why our static control system is always installed prior to the cleaning process to guarantee a neutralised substrate surface and therefore facilitate easier removal of all particles.

Technology

The special aerodynamic nozzle of the Xstream which is positioned close to the surface of the substrate generates, through the combination of vacuum in the cleaning module and web speed, an extremely high velocity air flow (>60m/s). The high velocity air flows along the substrate surface to the nozzle edge and into the cleaning module. The high velocity airflow breaks the boundary layer on the substrate and forces the particles that were trapped in this layer into the cleaning module. From the cleaning module the particles are transported to a filter unit.

Main applications

Especially suitable for paper, film, foil, laminate, non-woven etc.

Xstream System advantages

Application

- Removes > 99% of loose particles > 30 μm

- Can be retrofitted to all machine types

- Wear free, minimised maintenance

- Low investment cost

- Easy installation

Economical

- Increased profitability

- Reduced waste and down time

Ecological

- No consumables, no washing liquids

- 30% lower energy consumption compared to other systems in its class

Hildebrand Xstream non-contact web cleaning system combines the latest aerodynamic nozzle technology with a high speed vacuum airflow and substrate ionization prior to cleaning within one system. It is positioned above an idler roller for removal of all particles on paper, film, foil, laminate and non-woven products. As a representative of Hildebrand in the Netherlands we also supply other surface cleaning and electrostatic discharging systems.

End-of-Line inspection for the food industry

Jansen Control Systems supplies and maintains a range of end-of-line inspection systems. We supply our own checkweighers, FORTRESS metal detectors, SPARC X-ray systems, SOLLAU magnetic separators and HILDEBRAND electrostatic discharging and surface cleaning systems. Guarantee the quality of your product with one of our end-of-line systems. We’d be happy to help.